24/7 Customer Service - Call Us on -

1300 546 359

POST TENSIONING SYSTEM PERTH

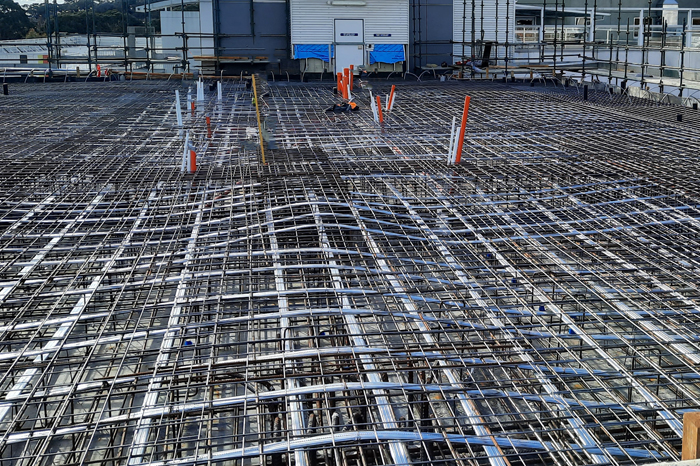

Post tensioning system makes use of steel cables for reinforcing concrete by applying compression after pouring concrete, hence the name. Galvanised flat ducts which are profiled using bar chairs along the part where tension is expected to occur in the concrete slab. 12.5 or 15.2 ACRS approved strand are inserted into the duct (known as tendons) and the concrete is poured over them. When the concrete has set to required strength, the tendons are stretched using hydraulic jacks. Once the

tendons have elongated to the specified length, they are pushed in position to maintain the level of tension even after removing the jacks. The duct is then grouted to protect against corrosion and to join the strand to the concrete pieces.

Post tensioning systems offer a number of advantages over regular cement slabs. Builders can design longer spans for floors or beams which reduces the number of columns required. This means longer column free floor areas which can be used for numerous purposes. Post tensioning systems also mean lower cost of materials, labour and formwork. Post tensioning system considerable reduces stress, shrinkage and cracking and the cracks that do form are held tightly together.

Thinner slabs are possible with post tensioning system as they can bear the same load. Also, for taller structures, it means more floors can be built within the original building height. Post tensioning systems assure that slabs are crack free and therefore waterproof slabs are possible. Post tensioning systems also allows us to build slabs on expansive or soft soils.

Post tensioning system makes use of steel cables for reinforcing concrete by applying compression after pouring concrete, hence the name. Galvanised flat ducts which are profiled using bar chairs along the part where tension is expected to occur in the concrete slab. 12.5 or 15.2 ACRS approved strand are inserted into the duct (known as tendons) and the concrete is poured over them. When the concrete has set to required strength, the tendons are stretched using hydraulic jacks. Once the

tendons have elongated to the specified length, they are pushed in position to maintain the level of tension even after removing the jacks. The duct is then grouted to protect against corrosion and to join the strand to the concrete pieces.

Post tensioning systems offer a number of advantages over regular cement slabs. Builders can design longer spans for floors or beams which reduces the number of columns required. This means longer column free floor areas which can be used for numerous purposes. Post tensioning systems also mean lower cost of materials, labour and formwork. Post tensioning system considerable reduces stress, shrinkage and cracking and the cracks that do form are held tightly together.

Thinner slabs are possible with post tensioning system as they can bear the same load. Also, for taller structures, it means more floors can be built within the original building height. Post tensioning systems assure that slabs are crack free and therefore waterproof slabs are possible. Post tensioning systems also allows us to build slabs on expansive or soft soils.

Our Products

Civil

Post Tensioning

Civil

Post Tensioning

As an organisation, We have made a commitment to understand our current and future clients needs and meet their requirements and strive to exceed their expectations.We recognise that people are the essence of any good business and that their full involvement enables their abilities to be used for our benefit.Our policy is also to meet the requirements of other interested parties and to address our social, environmental, charitable, regulatory, and legislative responsibilities.

Kingflex

Our Team

Joey Qian

Managing Director

Joe Kanga

General Manager