24/7 Customer Service - Call Us on -

1300 546 359

POST TENSIONING AUSTRALIA PERTH

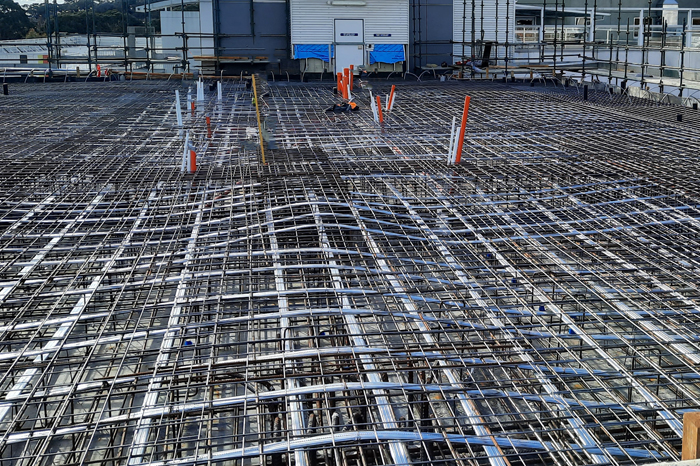

Post tensioning Australia is a method of concrete reinforcement by introducing a high-strength steel cable within the slab before pouring the concrete and then tensioning the cable. The internal stress that is produced within the steel cable counteracts the external pressure that is applied when the structure is put into use. Post tensioning Australia is usually done onsite by means of post-tensioning tendons within the concrete slabs in a manner similar to installing rebar.

Concrete as construction material is very stronger in compression than in tension while steel is strong in tension. Subjecting a concrete slab to compression and the embedded steel into tension before application of heavy loads combines the best of the two materials creating a stronger slab that has higher capacity to resist stress. This results in crack resistant concrete slabs also making it waterproof.

The use of post tensioning Australia to reinforce concrete can lead to construction of thinner floor slabs and/or longer spans between supports. This is a huge advantage and builders can now build large structures with more clear spaces allowing more architectural freedom and lesser material costs. Post tensioning Australia also causes reduction in the thickness of each floor in a building and the total weight of the structure and height of each level can also be significantly reduced.

Post tensioning Australia does not warrant any special considerations for the formwork apart from what is used in non-post-tensioned construction and the deck forms can be cycled as soon as the tendons are stressed, resulting in fast construction cycle times.

Post tensioning Australia is a method of concrete reinforcement by introducing a high-strength steel cable within the slab before pouring the concrete and then tensioning the cable. The internal stress that is produced within the steel cable counteracts the external pressure that is applied when the structure is put into use. Post tensioning Australia is usually done onsite by means of post-tensioning tendons within the concrete slabs in a manner similar to installing rebar.

Concrete as construction material is very stronger in compression than in tension while steel is strong in tension. Subjecting a concrete slab to compression and the embedded steel into tension before application of heavy loads combines the best of the two materials creating a stronger slab that has higher capacity to resist stress. This results in crack resistant concrete slabs also making it waterproof.

The use of post tensioning Australia to reinforce concrete can lead to construction of thinner floor slabs and/or longer spans between supports. This is a huge advantage and builders can now build large structures with more clear spaces allowing more architectural freedom and lesser material costs. Post tensioning Australia also causes reduction in the thickness of each floor in a building and the total weight of the structure and height of each level can also be significantly reduced.

Post tensioning Australia does not warrant any special considerations for the formwork apart from what is used in non-post-tensioned construction and the deck forms can be cycled as soon as the tendons are stressed, resulting in fast construction cycle times.

Our Products

Civil

Post Tensioning

Civil

Post Tensioning

As an organisation, We have made a commitment to understand our current and future clients needs and meet their requirements and strive to exceed their expectations.We recognise that people are the essence of any good business and that their full involvement enables their abilities to be used for our benefit.Our policy is also to meet the requirements of other interested parties and to address our social, environmental, charitable, regulatory, and legislative responsibilities.

Kingflex

Our Team

Joey Qian

Managing Director

Joe Kanga

General Manager